Air Operated Diaphragm Pumps

(In M.O.C:- Aluminium, SS-316, PP, PVDF, PTFE, etc.)

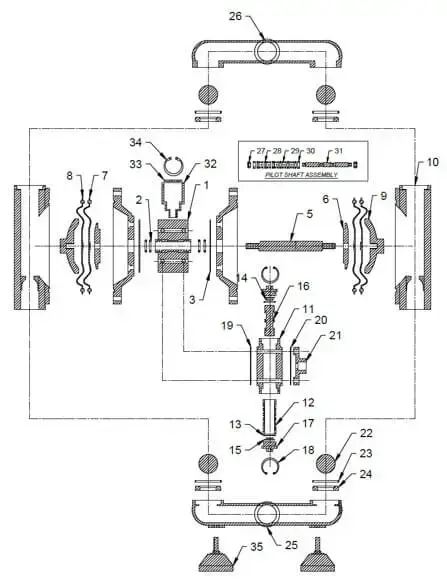

Air Operated Diaphragm Pumps (AODD) are versatile and robust devices powered by compressed air, capable of handling various fluids, including viscous and abrasive ones. They feature two flexible diaphragms that create a pumping action, making them suitable for applications from industrial processing to wastewater treatment. Known for their self-priming abilities, ability to run dry, and ease of maintenance, AODD pumps are ideal for hazardous environments in industries such as chemical manufacturing, mining, and food processing.

Air Operated

Diaphragm Pumps

* * M.O.C. VARIES AS PER APPLICATION

|

Sr No. |

Part Name | M.O.C. | Oty |

Sr No. |

Part Name | M.O.C. | Oty |

|---|---|---|---|---|---|---|---|

| 1 | Shaft Block | GFPP | 01 | 23 | Seat O Ring | Teflon | 04 |

| 2 | Main Shaft 'O' Ring | Neoprene | 04 | 24 | Ball Seat | SS-316 | 04 |

| 3 | Air-Cover Gasket | Non Asbestos | 02 | 25 | Suction Line | SS-316 | 01 |

| 4 | Air-Cover | Aluminium | 02 | 26 | Discharge Line | SS-316 | 01 |

| 5 | Main Shaft | SS-304 | 01 | 28 | Nyloc Nut | SS-304 | 02 |

| 6 | Holding Plate | Aluminium | 02 | 29 | Pilot Shaft O Ring | Neoprene | 06 |

| 7 | Back Up Diaphragm | Santoprene | 02 | 29 | Pilot Bush | Brass | 05 |

| 8 | Diaphragm | Teflon | 02 | 30 | Plain Bush | Brass | 02 |

| 9 | Lock-Nut | SS-316 | 02 | 31 | Pilot Shaft | SS-304 | 01 |

| 10 | Liquid Chamber | SS-316 | 02 | 32 | Exhauts | GFPP | 01 |

| 11 | Piston Block | GFPP | 01 | 33 | Exhauts Plate | PP | 01 |

| 12 | Piston Block Bush | Brass | 01 | 34 | Circlip | SS-304 | 01 |

| 13 | Piston Block Bush 'O' Ring | Neoprene | 06 | 35 | Mounting Pad | Rubber | 04 |

| 14 | Piston 'O' Ring | Neoprene | 03 | 36 | Liquid Chamber Lock bolt & Nut 3/8"X2" | SS-304 | 20 |

| 15 | Piston Ring | PTFE | 03 | 37 | Suction & Discharge Line Lock bolt & Nut 5/16"X 1 1/2" | SS-304 | 16 |

| 16 | Piston | Aluminium | 01 | 38 | Air Assembly Lock bolt & Nut 5/16" x 4" | SS-304 | 04 |

| 17 | Piston Block Cap | PP | 02 | 39 | Piston Block Allen Bolt 1/4" x 3 1/2" | SS-304 | 04 |

| 18 | Circlip | SS-304 | 02 | ||||

| 19 | Piston Block Gasket | Non Asbestos | 01 | ||||

| 20 | Piston Block Cover Gasket | Non Asbestos | 01 | ||||

| 21 | Piston Block Cover | GFPP | 01 | ||||

| 22 | NRV Ball | PTFE | 04 |

Advantages of Air Operated Diaphragm Pumps (AODD)

- Versatility: Capable of handling a wide range of fluids, including viscous, abrasive, and chemically aggressive liquids.

- Self-Priming: Able to prime themselves without the need for additional equipment.

- Dry Running: Can run dry without damage, ensuring reliability in various conditions.

- Ease of Maintenance: Simple design allows for easy cleaning and maintenance.

- Hazardous Environment Suitability: Safe for use in explosive or hazardous environments due to their air-powered operation.

- Adjustable Flow Rates: Flow and pressure can be easily adjusted by regulating the air supply.

- Portability: Lightweight and portable, making them easy to move and deploy as needed.

- Durability: Resistant to wear and tear, ensuring long-term reliability and reduced downtime.

- Cost-Effective: Often lower initial cost and operational expenses compared to other types of pumps.

More from us

Our other pumps

Horizontal Centrifugal

Non-Metallic Lined Pumps

The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc. A unique feature...

Horizontal Centrifugal

Non-Metallic Pumps

These pumps being used for corrosive application, utmost care is taken to reduce the number of joints and if available are sealed with TEFLON (PTFE) gaskets. Shaft being totally...

Horizontal Centrifugal

Metallic Pumps

Ideal for corrosive and abrasive fluids. Handles solids and stringy fibers with ease. Adjustments of clearances is easy when wear take place, repair cost reduced. Back pump-out...