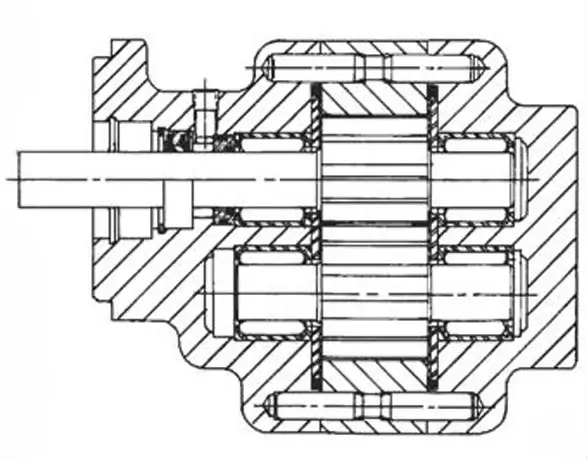

Gear Pumps

(In M.O.C:- CS, SS-304, SS-316, A-20, etc.)

Gear pumps are positive displacement pumps that use meshing gears to transfer fluids efficiently, ideal for viscous liquids like oils and chemicals. Known for precise flow rates and minimal pulsation, they are widely used in automotive, chemical, and food industries. Their robust, simple design ensures reliability, ease of maintenance, and long-term performance.

Advantages of Gear Pumps

- Precise Flow Rates: Delivers consistent and accurate fluid transfer.

- Handles Viscous Liquids: Ideal for thick fluids like oils and chemicals.

- Minimal Pulsation: Ensures smooth and steady operation.

- Durable: Robust construction for long-term reliability.

- High Pressure Handling: Capable of operating under high pressures.

- Simple Design: Easy to maintain and repair.

- Versatile Applications: Suitable for automotive, chemical, and food industries.

More from us

Our other pumps

Horizontal Centrifugal

Non-Metallic Lined Pumps

The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc. A unique feature...

Horizontal Centrifugal

Non-Metallic Pumps

These pumps being used for corrosive application, utmost care is taken to reduce the number of joints and if available are sealed with TEFLON (PTFE) gaskets. Shaft being totally...

Horizontal Centrifugal

Metallic Pumps

Ideal for corrosive and abrasive fluids. Handles solids and stringy fibers with ease. Adjustments of clearances is easy when wear take place, repair cost reduced. Back pump-out...