Horizontal Centrifugal Non-Metallic Lined Pumps

(M.O.C.: PVDF, ETFE, TEFLON (i.e.FEP, PFA, etc.))

The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc. A unique feature is the dove tail grooves provided on the metal casing and back plate.....

Horizontal Centrifugal

Non-Metallic Lined Pumps

Mechanical seal stationary ring-ceramic and rotary unit is external mounted Teflon bellow with GFT or

replaceable Silicon Carbide/Carbon face.

** All hardware are of SS

*** RATHI (love joy) make RRL flexible spacer type coupling.

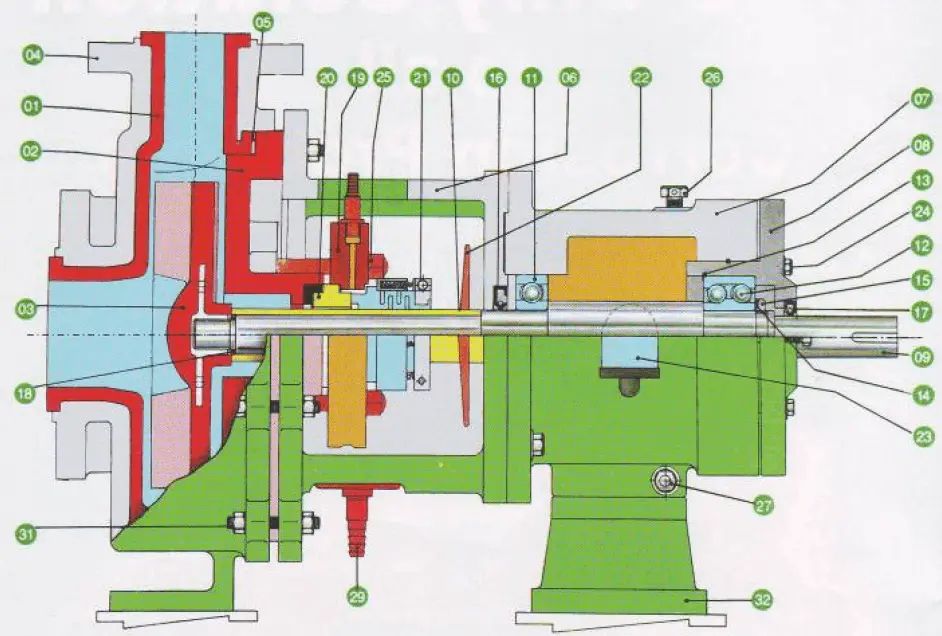

| 01 | Casing lining | PVDF/FEP/PFA | 17 | Oil seal | Neoprene |

| 02 | Back plate | PVDF/FEP/PFA | 18 | 0'ring | Teflon |

| 03 | Impeller | PVDF/FEP/PFA | 19 | Locating flange | Hylem |

| 04 | Casing armour | Cast Steel | 20 | Stationary ring of mech.Seal | * |

| 05 | Envelope gasket | PTFE | 21 | Rotary unit of mech.Seal | * |

| 06 | Adaptor | Cast lron | 22 | Deflector | Polypropylene |

| 07 | Bearing block | Cast lron | 23 | Costant oil leveler | Aluminum |

| 08 | Telescopic bearing cover | Cast lron | 24 | Hard wares | ** |

| 09 | Bare shaft | S.S./En-24 | 25 | Bolts for clamping mech.seal | ** |

| 10 | Shaft sleeve | Ceramic | 26 | Oil draining plug | Steel |

| 11 | Ball bearing(in board) | SKF | 27 | Oil during plug | Steel |

| 12 | Ball bearing(out board) | ZKL | 28 | Coupling | |

| 13 | Circlip | Spring steel | 29 | Drip tray | Polypropylene |

| 14 | Star washer | Spring Steel | 30 | Base plate | M.S.fabricated |

| 15 | Locknut | Steel | 31 | Bolts for mounting | S.S |

| 16 | Oil seal | Neoprene | 32 | Bearing block base | Cast lron |

Technical Features

- The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc.

- A unique feature is the dove tail grooves provided on the metal casing and back plate.

- This ensures a firm grip between the metal and lining material.

- A dynamically balanced, solid moulded, semi open impeller with metallic insert gives mechanical strength and durability.

Casing and Back Plate and Impeller

- Thick walled casing and back plate is made of PVDF,FEP, PFA Lining.

- Standard shell of cast iron, cast steel.

- Semi open impeller.

- It is one piece, robust construction, dynamically balanced & is provided with back vanes to minimize axial thrust for enhanced bearing life.

More from us

Our other pumps

Horizontal Centrifugal

Non-Metallic Lined Pumps

The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc. A unique feature...

Horizontal Centrifugal

Non-Metallic Pumps

These pumps being used for corrosive application, utmost care is taken to reduce the number of joints and if available are sealed with TEFLON (PTFE) gaskets. Shaft being totally...

Horizontal Centrifugal

Metallic Pumps

Ideal for corrosive and abrasive fluids. Handles solids and stringy fibers with ease. Adjustments of clearances is easy when wear take place, repair cost reduced. Back pump-out...