Thermic Fluid Pumps

(In M.O.C:- CS, SS-304, SS-316, A-20, etc.)

Thermic fluid pumps are designed for handling high-temperature fluids in heat transfer applications. Used in industries like chemical processing and power generation, they ensure safe and efficient circulation of thermal oils. Built for durability and reliability, these pumps are essential for maintaining consistent high-temperature operations.

Thermic Fluid Pumps

* * M.O.C. VARIES AS PER APPLICATION

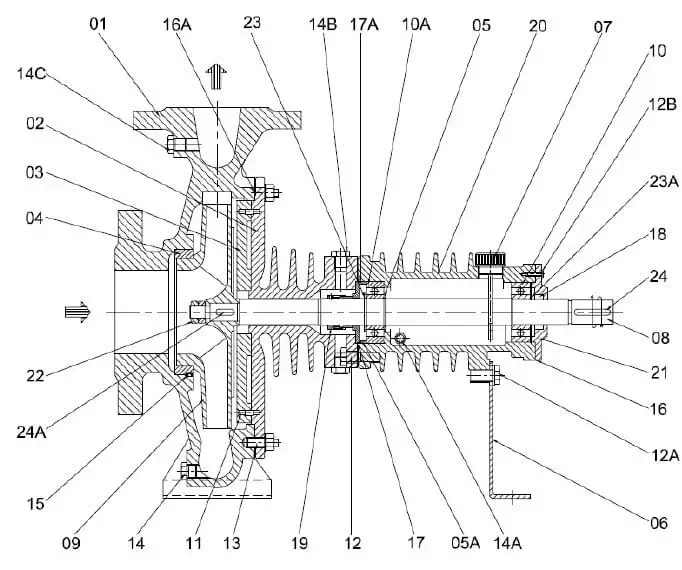

| Part No. | Description | M.O.C. |

|---|---|---|

| 1 | Suction casing | Ductile Iron, WCB, SS316 |

| 2 | Casing cover | Ductile Iron, WCB, SS316 |

| 3 | Cooling plate | Ductile Iron, WCB, SS316 |

| 4 | Wear ring | Bronze, CC50 |

| 5 | Spacer ring | Steel |

| 6 | Support foot | Ductile Iron |

| 7 | Oil dipstick | Steel |

| 8 | Shaft | SS316 |

| 9 | Impeller | Ductile Iron, WCB, SS316 |

| 10 | Ball bearing | Steel |

| 11 | Screw | Ductile Iron, WCB, SS316 |

| 12 | Screw | Ductile Iron, WCB, SS316 |

| 13 | Stud | Ductile Iron, WCB, SS316 |

| 14 | Plug | Ductile Iron, WCB, SS316 |

| 15 | Grub screw | Ductile Iron, WCB, SS316 |

| 16 | Gasket | Paper Gasket |

| 17 | O-ring | Viton |

| 18 | Radial seal ring | Viton |

| 19 | Mechanical seal | Lecrolloy / Carbon |

| 20 | Bearing frame | Ductile Iron / Cast Iron |

| 21 | Bearing cover | Ductile Iron |

| 22 | Locking nut | Steel |

| 23 | Circlip | Steel |

| 24 | Key-Wey | SS316 |

Advantages of Thermic Fluid Pumps

- High-Temperature Handling: Designed to manage extreme temperatures safely.

- Efficient Heat Transfer: Ensures effective circulation of thermal oils.

- Durable Construction: Built to withstand harsh conditions for long-term use.

- Reliability: Provides consistent performance in critical operations.

- Versatile Applications: Suitable for industries like chemical processing and power generation.

- Safety: Reduces risks associated with high-temperature fluid handling.

- Maintenance: Typically easy to maintain and repair.

More from us

Our other pumps

Horizontal Centrifugal

Non-Metallic Lined Pumps

The hi-tech lining process involves high pressure moulding at high temperature to ensure uniform thickness of lining free from cavities, air pockets, cold flows, etc. A unique feature...

Horizontal Centrifugal

Non-Metallic Pumps

These pumps being used for corrosive application, utmost care is taken to reduce the number of joints and if available are sealed with TEFLON (PTFE) gaskets. Shaft being totally...

Horizontal Centrifugal

Metallic Pumps

Ideal for corrosive and abrasive fluids. Handles solids and stringy fibers with ease. Adjustments of clearances is easy when wear take place, repair cost reduced. Back pump-out...